Common Barcode Symbologies

Interleaved 2 of 5 (“I” 2 of 5)

Incorporates numeric characters only

Incorporates numeric characters only

Can be of variable length, but must have an even number of characters.

Common applications include warehousing, product/container identification, general industrial and automotive.

Often used in UPC Shipping Container Code formats.

Quiet zone is ten times the width of the narrow bar.

The Interleaved 2-of-5 bar code is a bi-directional, continuous, self-checking numeric bar code. It uses a series of wide and narrow bars or spaces to represent each character, and each symbol employs unique Start and Stop elements.

The symbology requires an even number of characters to be interleaved together. The bars represent data characters occupying the odd positions, and the spaces represent characters in the even positions. Additionally, each data character must be composed of five elements, two wide and three narrow. Character pairing begins with the most significant digit (left most digit) and continues two at a time until all characters are used. The Start element consist of two narrow bars while the Stop element combines a wide and narrow bar.

Code 39 (3 of 9)

Incorporates alphanumeric characters.

Incorporates alphanumeric characters.

Can be of variable length.

Check digit is optional but normally not used.

Common applications include LOGMARS (Department of Defense), GSA, AIAG (automotive), general industrial and HIBCC (health industry).

Quiet zone is 10 times the width of the narrow bar. The 3 of 9 bar code is a variable-length, bi-directional, discrete, self-checking, alphanumeric bar code. Its data character set contains 43 characters: 0-9, A-Z, -, ., $, /, +, % and space. Three of the nine elements are wide and six are narrow. A common character (*) is used exclusively for both a Start and Stop character. The Start/Stop characters must be included in every bar code. It’s the Start/Stop pattern that allows symbols to be scanned bi-directionally. Code 39’s flexibility to encode both text and numbers has contributed to its widespread use.

Code 128

Employs alphanumeric characters.

Employs alphanumeric characters.

Can be of variable length.

Common applications include general industrial, inventory control and retail container marking.

Often used in UCC/EAN Serial Shipping Container Code formats.

Quiet zone is ten times the width of the narrow bar.

This code has 128 characters. Like Code 39, Code 128 offers variable-length symbols. But at the same time, Code 128 is more compact. Code 128 allows the user to encode any character found on a CRT keyboard, including the control characters. This gives the user more encoding versatility than previously possible in an industrial bar code.

Pharmacode

Pharmacode, also known as Pharmaceutical Binary

Pharmacode, also known as Pharmaceutical Binary

Code, is a barcode standard, used in the pharmaceutical industry as a

packing control system. It is designed to be readable despite printing errors.

It can be printed in multiple colors as a check to ensure that the remainder of

the packaging (which the pharmaceutical company must print to protect itself

from legal liability) is correctly printed.

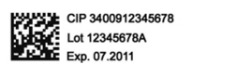

Data MatrixCode

A Data Matrixcode is a two-dimensional matrix barcode consisting of black and white “cells” or modules arranged in either a square or rectangular pattern. The information to be encoded can be text or raw data. Usual data size is from a few bytes up to 1556 bytes . The length of the encoded data depends on the symbol dimension used. Error correction codes are added to increase symbol strength: even if they are partially damaged, they can still be read. A Data Matrix symbol can store up to 2,335 alphanumeric characters.

A Data Matrixcode is a two-dimensional matrix barcode consisting of black and white “cells” or modules arranged in either a square or rectangular pattern. The information to be encoded can be text or raw data. Usual data size is from a few bytes up to 1556 bytes . The length of the encoded data depends on the symbol dimension used. Error correction codes are added to increase symbol strength: even if they are partially damaged, they can still be read. A Data Matrix symbol can store up to 2,335 alphanumeric characters.

Glossary of Terms for Barcodes

Application Identifier – A character (or set of characters) that uniquely defines the specific use of the data encoded in the bar code symbol following the data identifier. Also known as a Flag Character.

Ladder Code – A bar code printed in a vertical position such that the bars can be thought of as rungs on a ladder. Contrast with Picket Fence.

Matrix Symbols – A symbol which appears as a checker board; they are most likely square in shape, and contain some form of unique “finder pattern,” which distinguishes them from others and provides a decoding reference for

scanners.

Picket Fence Code – A bar code printed in a horizontal position such that the individual bars appear like the slats in a picket fence. See Ladder Code.

Print Quality – The measure of compliance of a bar code symbol to the requirements of dimensional tolerance, edge roughness, spots, voids,

Quiet Zone – A character used to check the integrity of the preceding bar code symbol. A check character is normally found at the end of the data encoded within the bar code.

Verification – The technical process by which a Bar Code symbol is evaluated to determine whether it meets the

specification for the specified symbol.

X Dimension – The dimension of the narrowest element (bar or space) in a bar code symbol.

2-Dimensional Symbology – A machine readable symbol composed of rows of encrypted data arranged in a rectangular or square pattern. The rows of data may be composed of bar code strips, “stacked” to form the two-dimensional block pattern or arranged as a checkerboard “matrix” of typically square elements

Resolution: A measure of the narrowest code element that can be used by a specific reader. The higher the resolution, the smaller the value, and the narrower the element. Measured in mils (1/100inch) or mm.

Contrast: The difference in reflectance between a bar code’s light and dark elements, measured at a specific wavelength. A minimum contrast value is required by scanners, as listed in their specification tables.

Depth of Field: The difference between maximum and minimum reading distance.

Standards which control the printing of barcodes:

ISO 15415 2D Print Quality Specification

ISO 15416 1D Print Quality Specification

ISO 15417 Code 128 Symbology Specification

ISO 16022 DataMatrix Symbology Specification

ANSI Grading Chart

Barcode Structure/Quality:

List of Application Identifiers

All dates are formatted as YYMMDD.

y in the AI gives a number of decimal places.

| Code |

Description |

Data length (without Al) |

| 00 |

Serial Shipping Container Code (SSCC) |

18 |

| 01 |

Global Trade Item Number (GTIN) |

14 |

| 02 |

GTIN of Contained Trade Items |

14 |

| 10 |

Batch/Lot Number |

up to 20 |

| 11 |

Production Date |

6 |

| 12 |

Due Date |

6 |

| 13 |

Packaging Date |

6 |

| 15 |

Sell by Date (Quality Control) |

6 |

| 17 |

Expiration Date |

6 |

| 20 |

Product Variant |

2 |

| 21 |

Serial Number |

variable up to 20 |

| 30 |

Count of items |

variable up to 8 |

| 37 |

Number of units contained |

variable up to 6 |

How to choose the correct barcode

The rules set out below will help you choose the correct barcode for each level of packaging.

1. If the product is a consumer unit (it could be sold at a retail point of sale), use an EAN-13, UPC-A, EAN-8 or UPC-E barcode to identify it.

2. If the product is a traded unit (a product that will not be sold at a retail point of sale), any of the GS1 bar codes may beused. However if barcodes are printed direct onto fibreboard packaging, ITF-14 symbols may need to be used.

3. If the traded unit could also be sold at a retail point of sale (eg, a box of 24 cans of beer), it must be barcoded with at least one EAN-13 or UPC-A at a magnification of at least 150%.

4. If EAN-13 or UPC-A symbols are printed on a traded unit, make sure that the packaging materials are of an adequate quality to allow for scannable symbols to be printed. The outer packaging of the traded unit must also obscure all the barcodes that appear on the products inside it.

5. If the traded unit has a short shelf life, say less than 42 days, use a GS1-128 bar code to encode the GTIN for the item and its expiry date. Most users will not be able to achieve a symbol of adequate quality unless they use print and apply labels or use white kraft board as the substrate.

6. If the traded unit has to be barcoded with extra information, such as a batch number or variant number, use a GS1-128 bar code to encode this information together with the GTIN.

7. If the traded unit is of variable measure, use a GS1-128 barcode, which will encode the measure (often the weight in kilograms) alongside the GTIN.

8. If pallets are being labelled, only GS1-128 barcodes must be used on the label.

Barcode Label Software - Getting Started

If you deal with barcodes, then you know you need a reliable way to create and transfer barcodes to a printer. That’s where barcode  software comes in.

software comes in.

Barcode software can range from a simple barcode generator to a complex program used to harness the power of a large database.

You may be a business owner, a manager, or an individual selling just a few products. But regardless of your role, you need to produce high quality barcodes.

If you’re a high volume seller, then you’ll want software that easily interfaces with your database and can communicate in native printer languages.

If you sell products to a vendor or middleman, then you’ll need the ability to print a variety of different barcodes, using multiple fonts.

If you have a small retail operation that mostly sells in-house products, then you’ll want to coordinate your barcode software with your barcode scanner, and find a software program that will print barcode labels quickly and easily.

Barcode software – Questions to ask

Before choosing a barcode software package, take some time to evaluate your needs.

(1) Are you creating and printing a lot of barcodes for business use?

(2) Do you need access to many different barcode fonts?

(3) Will you need to import data or export barcodes from other software programs?

(4) Are you planning to add design features to your barcode labels?

AIS offer the following barcode software packages

Zebra Designer

BarTender

Easy Label

Unattended Scanning Application - things to consider

Through the years, we have found that a little up-front planning and a few simple questions can ensure a successful fixed scanner application.

There are many different types of fixed mount scanners – one of the most noticeable differences is in the scan patterns emitted.

Although the most common type of scan pattern is a straight line, other patterns include: fixed raster line, moving raster, and omnidirectional scanners

The following questions should help you to plan your own installation, by considering such criteria as:

How fast is the label moving past the scanner?

How far away is the label and how much will that distance vary?

Can the scanner read your label at the desired distance?

How does the scanner know when to read and output the label data?

Probably the most complicated part of a moving-beam scanner application is determining whether the scanner is fast enough to scan a particular label reliably.

Although a scanner can successfully read a barcode in two scans, experts generally recommend a minimum of five scans to read a well-printed label reliably.

The following formulas are useful for calculating how many actual guaranteed scans will occur given any combination of label size, speed, and orientation.

The number of effective scans from a passing label is determined by:

- Scan rate

- Direction of label travel

- Speed at which the label passes

- Barcode label dimensions

In planning your installation you should also consider the following –

Can you place the label in the ladder orientation? This orientation affords more chances to read a damaged label, and label placement is not as critical as in a picket fence orientation. In general, resort to a picket fence setup only if the ladder mode won’t work in your application.

Have you avoided tilt, pitch, and skew of the label as much as possible?

Have you avoided the scanner’s specular reflection zone? The specular reflection zone is a narrow zone in which direct, non-diffused light returns to the scanner blinding the scanner and makes reading a label impossible.

Optical throw and depth of field ?

System Considerations ?

Scanner Mounting and Environment ?