The ALTech machine of the month is an ALstep built for an important producer of plastic containers.

In the customer’s factory, every injection moulding machine is equipped with a robot that takes each product from the mould and places it on an out-feed conveyor. The customer requested that the product be labelled with labels of various shapes and dimensions, using the flexibility of the robot to present the product correctly orientated in front of the labeller.

In the customer’s factory, every injection moulding machine is equipped with a robot that takes each product from the mould and places it on an out-feed conveyor. The customer requested that the product be labelled with labels of various shapes and dimensions, using the flexibility of the robot to present the product correctly orientated in front of the labeller.

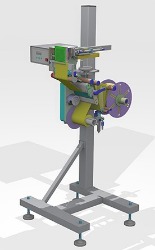

The machine supplied is an ALstep M, equipped with the AC32 pneumatic application system. When the  robot presents the part in front of the labeller, the ALstep applies the label onto the side of the container using a tamp-blow concept. The unique design of the AC32 generates vacuum that keeps the label on the pad by using a fan, allowing the system to manage different label sizes without the need to change the vacuum pad. This feature was greatly appreciated by the customer who after the initial test of the first machine ordered another 20 units.

robot presents the part in front of the labeller, the ALstep applies the label onto the side of the container using a tamp-blow concept. The unique design of the AC32 generates vacuum that keeps the label on the pad by using a fan, allowing the system to manage different label sizes without the need to change the vacuum pad. This feature was greatly appreciated by the customer who after the initial test of the first machine ordered another 20 units.

If you have any queries on this solution or have an automatic labelling requirement, please do not hesitate to contact us.